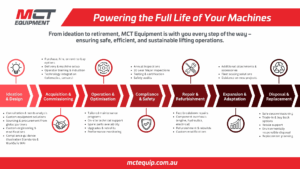

When it comes to investing in lifting machinery such as cranes, telehandlers, forklifts, and specialised equipment, the journey doesn’t start with a purchase — and it doesn’t end once the machine leaves the yard. At MCT Equipment, we pride ourselves on being more than just a supplier. We’re a full lifecycle partner who supports you from the earliest stages of equipment selection all the way through to responsible disposal and replacement.

By choosing MCT Equipment, businesses in mining, construction, marine and industrial operations across Australia gain access to world-class machinery, expert technical support, and compliance-focused services that ensure safety, efficiency, and long-term performance.

In this blog, we’ll take you step by step through how MCT Equipment can help clients at every stage of a lifting machine’s life — from the cradle of ideation to its eventual end-of-life.

-

Cradle – Ideation & Design

The first stage in any lifting machine’s lifecycle is about planning, designing, and selecting the right equipment. Getting this step right is critical to avoid costly mistakes down the track.

- Consultation & Needs Analysis – We take the time to understand your site conditions, operational requirements, and lifting challenges. Whether you’re working underground, in confined construction zones, or across expansive mining operations, our team ensures we recommend the most suitable solution.

- Custom Equipment Solutions – Every operation is different, which is why we advise on the most effective machine type for your task, be it a telehandler, crane, forklift, or a custom designed machine or attachment.

- Sourcing & Procurement – Through our strong partnerships with global leaders such as JMG Cranes, Magni Telescopic Handlers, Hoeflon Mini Cranes, Smart Group and Cimolai Technologies we bring innovative, reliable, and efficient lifting machines to the Australian market.

- Custom Engineering – Our in-house expertise means we can design and adapt attachments, accessories, or machine modifications so your lifting solution perfectly fits your application.

- Compliance Guidance – Safety is non-negotiable. Every proposed solution is reviewed against Australian Standards and WorkSafe WA regulations, ensuring compliance from the very beginning.

-

Acquisition & Commissioning

Once the right machine is identified, the focus shifts to acquisition and integration into your operations.

- Sales & Hire Options – Flexibility is key. We provide outright purchase, short-term and long-term hire, and even rent-to-buy solutions to suit different budgets and project timelines.

- Delivery & Installation – MCT Equipment doesn’t just drop machines at your site; we provide commissioning services to make sure equipment is properly set up and ready for use.

- Operator Training & Induction – We deliver hands-on training and compliance-focused induction, so your team is both safe and competent when operating new machinery.

- Technology Integration – Modern lifting machines often include telematics, safety sensors, and productivity tracking systems. We help integrate these technologies to maximise efficiency and oversight.

-

Operation & Optimisation

Once machines are in operation, the priority becomes maximising uptime and efficiency while minimising downtime and unexpected costs.

- Planned Maintenance Programs – We create tailored service schedules to ensure your equipment runs smoothly and avoids unnecessary breakdowns.

- On-Site Support – Our fleet of mobile technicians can respond to breakdowns across WA, providing rapid repairs to get you back online quickly.

- Spare Parts Supply – We stock a wide range of genuine OEM parts locally, ensuring quick turnaround times and reducing the impact of equipment failures.

- Upgrades & Retrofits – Extend the value of your machines with upgrades like new attachments, safety systems, or software updates.

- Performance Monitoring – Through usage tracking and reporting, we help clients optimise productivity, reduce wear and tear, and identify opportunities for efficiency gains.

-

Compliance & Safety

Compliance isn’t just about ticking boxes — it’s about ensuring the safety of workers and reliability of equipment.

- Annual Inspections – Our inspection services ensure machines meet AS 2550.1 requirements and comply with WorkSafe WA standards.

- Third-Party Testing Coordination – We work with certified providers to arrange load testing, NDT (non-destructive testing), and compliance checks.

- Safety Audits – Our team identifies risks before they become incidents, ensuring machines remain fit-for-purpose.

- Documentation & Recordkeeping – We maintain thorough records of service histories, inspection logs, and compliance reports, providing transparency and peace of mind.

-

Repair, Refurbishment and Major Inspections

Even the most reliable machines require repairs and overhauls during their working life or an extension of life with a Major Inspection

- Breakdown Repairs – Our technicians provide fast, responsive repair services to minimise costly downtime.

- Component Overhaul – From engines to hydraulics and electrical systems, we have the expertise to perform full component overhauls.

- Major Inspections – MCT can prepare a work scope thru utilization, OEM specifications and industry requirements to ensure a cost effective and quick turn around for your major inspection compliance

- Refurbishment & Rebuilds – Instead of replacing aging machines, clients can extend their lifecycle with a cost-effective refurbishment or full rebuild.

- Custom Modifications – As operations evolve, so too do equipment needs. We can modify machines to adapt to new site conditions or project requirements.

-

Expansion & Adaptation

As businesses grow, their lifting needs expand. MCT Equipment helps clients adapt and scale their fleets.

- Additional Attachments & Accessories – By adding new accessories, machines can be repurposed for multiple applications, increasing ROI.

- Fleet Scaling Solutions – We help businesses expand or rotate fleets, whether that means adding brand-new machines or replacing outdated ones.

- Consulting on New Projects – As new projects arise, we provide expert guidance on choosing the best-fit lifting solutions.

-

End-of-Life – Disposal & Replacement

Every machine eventually reaches the end of its useful life. At this stage, MCT Equipment ensures a responsible and cost-effective transition.

- Decommissioning Services – We handle the safe removal of machines from service.

- Trade-In & Buyback Options – Clients can offset the cost of new equipment by trading in older machines.

- Resale Support – For machines still holding value, we assist with remarketing or selling assets.

- Environmentally Responsible Disposal – Where resale isn’t possible, we ensure machines are recycled and disposed of responsibly.

- Replacement Planning – We guide businesses in transitioning to next-generation lifting solutions, ensuring continuity of operations.

Why Partner with MCT Equipment?

At MCT Equipment, we don’t see ourselves as just a supplier. We’re a trusted partner that helps you achieve safer, more efficient, and more sustainable lifting operations. Whether it’s selecting the right telehandler for a construction project, ensuring cranes meet inspection standards, or supporting a mining company with fleet-wide refurbishments, our team delivers end-to-end lifecycle solutions.

In short, MCT Equipment is with you every step of the way — from helping design the right lifting solution, keeping it safe and productive, and responsibly managing its retirement or replacement.